JPratt Designs Partners With TechForm: Premium Platinum Casting House

At JPratt Designs, we consistently look for ways to improve our jewelry offerings. Recently we partnered with a leading platinum casting house, TechForm, to elevate the integrity of our pieces. Through this partnership, we can offer superior-quality platinum rings, necklaces, earrings, and bracelets, ensuring only the best for our clients.

The Platinum Jewelry Casting Process

Platinum jewelry casting is exceptionally challenging because of the metal’s high melting temperature. Specialized equipment and techniques are required to achieve high-quality castings. Platinum solidifies extremely fast and develops defects if it cools before the entire piece has a chance to fill with metal. Platinum jewelers apply two main casting processes:

-

Lost wax casting jewelry

Lost wax casting jewelry is first modeled or 3D printed in wax, then surrounded by plaster. The jeweler heats the entire model to melt the wax out, leaving a cavity behind. They then pour molten platinum into the cavity, let it cool, and wash the plaster away to reveal the cast piece.

-

Clean-casting jewelry

Clean-casting jewelry goes through the same process as lost wax casting. However, the jeweler uses a centrifugal machine to throw the molten metal into the plaster mold.

Why We Chose TechForm for Platinum Casting

TechForm is the industry leader in platinum casting. The company uses its experience with medical and aerospace manufacturing to offer superior jewelry-casting services. It focuses on precision and quality, and partnering with TechForm allows us to produce more resilient custom jewelry.

TechForm’s sophisticated shell-casting process

TechForm developed a unique process that preserves even the finest details of a design when the piece is cast in metal. Not only is the jewelry casting flawless on the outside, but the metal is fully dense on the inside, something not many casters can achieve in platinum. The company can cast jewelry from 3D printed models, vulcanized silicone rubber molds, and hand-carved waxes.

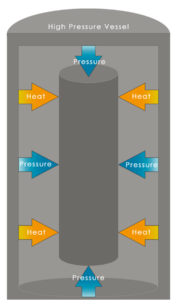

Hot Isostatic Pressing (HIP)

When molten platinum is solidifying, it tends to form micro “gaps” between the atoms called porosity. It is just the nature of the metal. TechForm is the only specialized jewelry caster that has the equipment in-house to virtually eliminate internal porosity in platinum jewelry castings. This process, called Hot Isostatic Pressing, or HIP, puts the finished platinum castings under extreme heat and pressure to squeeze out all of the “gaps” and bond the atoms together like they were never there. This ensures there are no voids or hollow areas inside the jewelry casting that could cause a prong or other feature to break.

Quality Assurance

TechForm prides itself on its aerospace-level quality standards, and its QA system is ISO 9001 and 14001 compliant. The jewelry casting company trains all employees on quality assurance methods and continuously improves its processes with innovative technologies.

How Partnering With TechForm Elevates Our Platinum Range

JPratt Designs and TechForm is a matchless partnership. Associating with such an esteemed casting house allows us to offer our customers even higher-quality products. We have been crafting custom jewelry since 1988, gathering invaluable industry knowledge. With TechForm in the mix, we can increase our expertise and technical expertise to your benefit.

Together, we can create stronger and more elaborate platinum jewelry designs of the highest caliber. Using TechForm’s sophisticated casting process for our jewelry, our customers get medical and aerospace-grade precision alongside authentic creativity.

Why Choose Platinum Jewelry?

When comparing platinum, silver, and white gold, platinum often triumphs. It’s 30 times rarer than gold and has long been admired for its brilliant white shine. Here are four reasons to choose platinum for your jewelry investment:

Platinum is strong and durable

Platinum is a dense metal that is stronger and more ductile than gold and silver. It offers superior resistance to everyday wear and tear because any noticeable effects can be easily and quickly smoothed back over with professional polishing. It feels heavier in your hand and makes the best material for gemstone-gripping claws in engagement rings because of its exceptional durability.

Platinum ages well

Platinum is naturally bright white, unlike white gold, which is naturally yellow so it has to be plated with rhodium to achieve the same look. That thin layer wears over time and must be replated to maintain the bright white high polish. After years of wear, platinum jewelry will never lose its natural shine and whiteness. What’s more, platinum develops a patina over time – meaning it develops a slightly frosted finish as it ages, making for beautiful heirloom jewelry.

Platinum makes diamonds look brighter

Diamonds are known for their reflectivity, and the color of a ring will affect how a diamond sparkles. Many prefer silver or white metals to bring out the stone’s color. Platinum is the brightest and whitest precious metal and pairs brilliantly with white diamonds.

Platinum is hypoallergenic

Gold and silver are very soft. Jewelers typically mix them with other metals to create alloys that are hard enough to use in jewelry creation. Sometimes these alloys contain nickel and other base metals that can irritate sensitive skin. Platinum alloys, on the other hand, are completely hypoallergenic. Quality platinum jewelry is exceedingly pure and contains 95% platinum. The other 5% is typically another pure platinum group metal like ruthenium.

Cast a Custom Platinum Piece With JPratt Designs

If you are looking for custom jewelry, JPratt Designs, partnered with TechForm, can help bring your visions and designs to life with platinum rings, necklaces, bracelets, and earrings that will last a lifetime.

Getting a professionally made piece is far superior to buying a piece of jewelry with unknown metal origin. Explore our bridal, women’s, and men’s jewelry range for inspiration, or contact JPratt Designs to start your custom jewelry journey today.